The PET Plastic Drinking Mineral Water Machine Bottle Water Manufacturing Machinery Bottled Drinking Water Production Line is a dependable and efficient system creating top-notch bottled water. This manufacturing line was created to manage (polyethylene terephthalate) plastic containers, which are lightweight, durable, and recyclable.

Utilizing state-of-the-art technology, this produces great-tasting and mineral pure water. This product possesses unique and simple design to use that makes it possible for a smooth manufacturing and straightforward procedure. The grade of water is examined through numerous tests ensuring clients receive crystal clear, clean, and safe drinking water.

This manufacturing line is great for organizations that want to create normal water for the big market. It can create containers in a variety of sizes starting from 250ml to 5L. Additionally, it offers alternatives for customizing the bottles with labels and logos, perfect for advertising and branding purposes.

The apparatus's easy procedure enables effortless setup and upkeep, reducing downtime. Having a capacity of creating over 1,200 bottles each hour(20 containers every single minute), this manufacturing line was designed for fast and efficient processing making this perfect for companies who need to create water quickly.

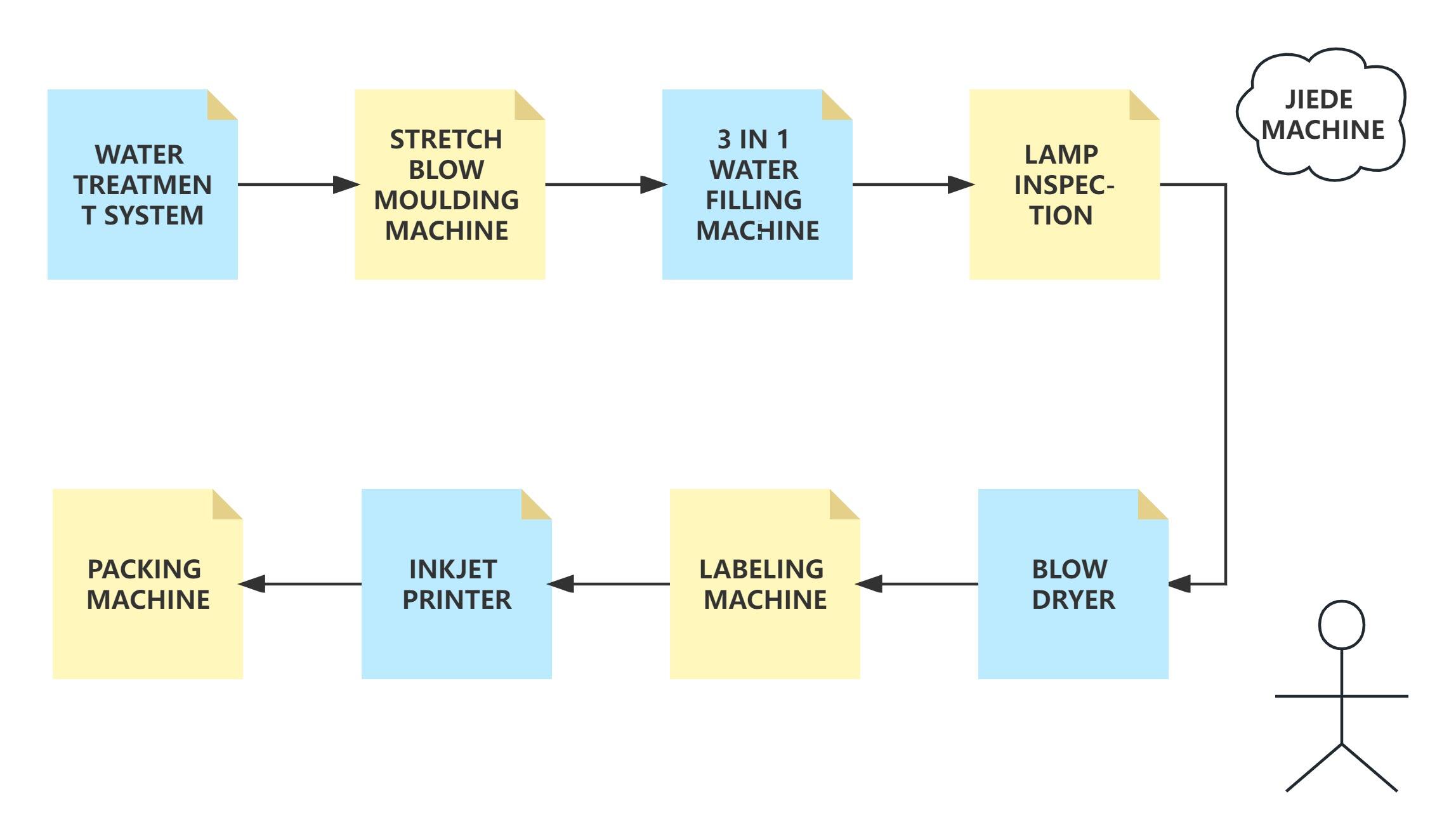

The manufacturing line includes few important components, including the water therapy system, container blowing and filling system, labeling device, and packaging system. These systems come together seamlessly, creating clean, pure, and hygienic bottled water.

In addition, the PET Plastic Drinking Mineral Water Machine Bottle Water Manufacturing Machinery Bottled Drinking Water Production Line was produced with higher level technology, causing low power usage and cost-efficient manufacturing. This makes it well suited for businesses that are seeking to reduce their working expenses while providing top quality water to clients.

Mold | CGF8-8-3 | CGF14-12-5 | CGF16-16-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-15 | ||||||||

Production capacity(B/H) | 2000-3000 | 3000-3500 | 3500-5000 | 5000-7000 | 7000-12000 | 12000-15000 | 15000-20000 | 20000-24000 | 24000-30000 | ||||||||

Suitable bottle shape | Circular or Square | ||||||||||||||||

Bottle diameter(mm) | Φ50-Φ95 | ||||||||||||||||

Washing | Aseptic Water | ||||||||||||||||

Total power | 2.5 | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 | ||||||||

Weight (kg) | 1800 | 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 | ||||||||

Overall dimensions(mm) | 1800*1200 | 2050*1550 | 2400*1750 | 2550*1850 | 3000*2150 | 4200*2700 | 4700*3200 | 6500*3350 | 7200*3650 | ||||||||

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy