Mold | RCGF8-8-3 | RCGF14-12-5 | RCGF16-16-6 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-10 | RCGF40-40-12 | RCGF50-50-15 | RCGF60-60-15 | ||||||||

Production capacity(B/H) | 1000-2000 | 2000-3500 | 3500-5000 | 5000-7000 | 7000-12000 | 12000-15000 | 15000-20000 | 20000-24000 | 24000-30000 | ||||||||

Suitable bottle shape | Circular or Square | ||||||||||||||||

Bottle diameter(mm) | Φ50-Φ95 | ||||||||||||||||

Washing | Juice/Hot tea/Flavor Drink/Energy Drink | ||||||||||||||||

Total power | 2.5 | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 | ||||||||

Weight (kg) | 1800 | 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 | ||||||||

Overall dimensions(mm) | 1800*1200 | 2050*1550 | 2400*1750 | 2550*1850 | 3000*2150 | 4200*2700 | 4700*3200 | 6500*3350 | 7200*3650 | ||||||||

JIEDE

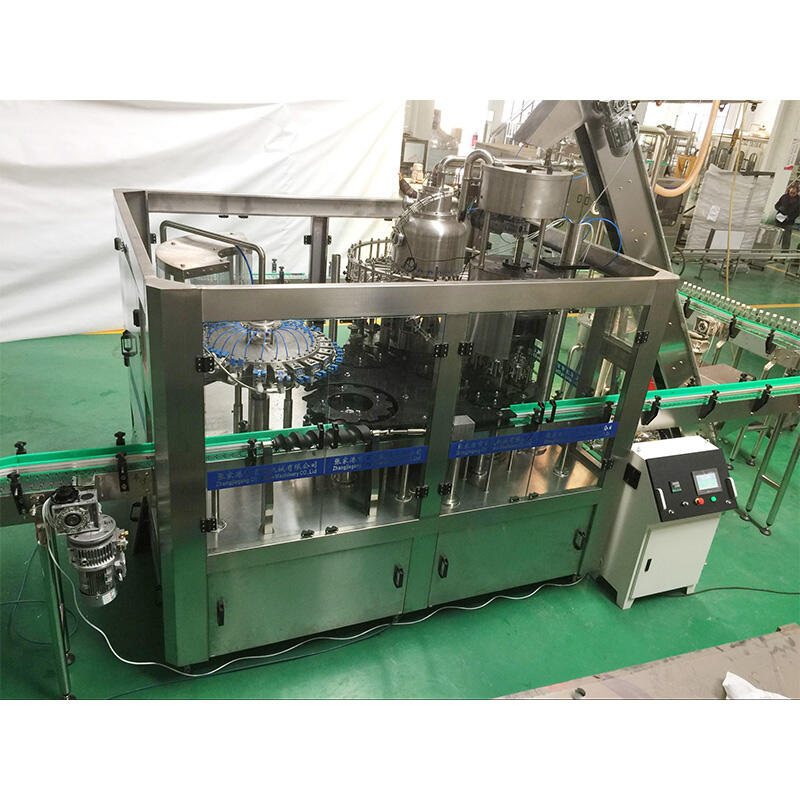

Introducing the No Maintenance Plate Type Sterilization Bottled Juice Filling Machine by Jiede - the ultimate solution for your juice packaging needs.

Created to make your juice procedure is bottling. Using its plate is advanced type system, it means that your beverages are safe and hygienic for consumption. The device is equipped with state-of-the-art filling technology, which ensures that each and every bottle is filled accurately and consistently, providing you with a reliable and process is efficient.

The biggest features is that no upkeep is needed by it. It really is built to withstand long hours of constant procedure without the need for regular repairs or upkeep, this means you can focus on running your business rather than concern yourself with machine downtime.

Super easy and user-friendly to work. It comes with a touch screen control panel that allows you to adjust and personalize the parameters that are filling suit your unique bottling requirements. Additionally, the machine features a high-speed speed is filling of to 300 bottles each and every minute, making it ideal for large-scale production, and may be customized to undertake bottles of different sizes.

Manufactured by Jiede, a reputable brand name is known for producing gear is high-quality. All parts associated with device are made of food-grade materials, ensuring that your beverages are not contaminated throughout the bottling process.

To ensure that your purchase is protected, Jiede delivers a warranty is comprehensive the machine, giving you reassurance comprehending that you are purchasing a reliable, high-quality piece of equipment.

The No Maintenance Plate Type Sterilization Bottled Juice Filling Machine by Jiede is an excellent investment for any business that wants to streamline its bottling process and enhance its productivity.

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy