Mold | CGF8-8-3 | CGF14-12-5 | CGF16-16-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-15 | ||||||||

Production capacity(B/H) | 2000-3000 | 3000-3500 | 3500-5000 | 5000-7000 | 7000-12000 | 12000-15000 | 15000-20000 | 20000-24000 | 24000-30000 | ||||||||

Suitable bottle shape | Circular or Square | ||||||||||||||||

Bottle diameter(mm) | Φ50-Φ95 | ||||||||||||||||

Washing | Aseptic Water | ||||||||||||||||

Total power | 2.5 | 3 | 3.5 | 4 | 5.5 | 7.5 | 11 | 15 | 20 | ||||||||

Weight (kg) | 1800 | 2200 | 2800 | 3000 | 4500 | 6000 | 9000 | 15000 | 18000 | ||||||||

Overall dimensions(mm) | 1800*1200 | 2050*1550 | 2400*1750 | 2550*1850 | 3000*2150 | 4200*2700 | 4700*3200 | 6500*3350 | 7200*3650 | ||||||||

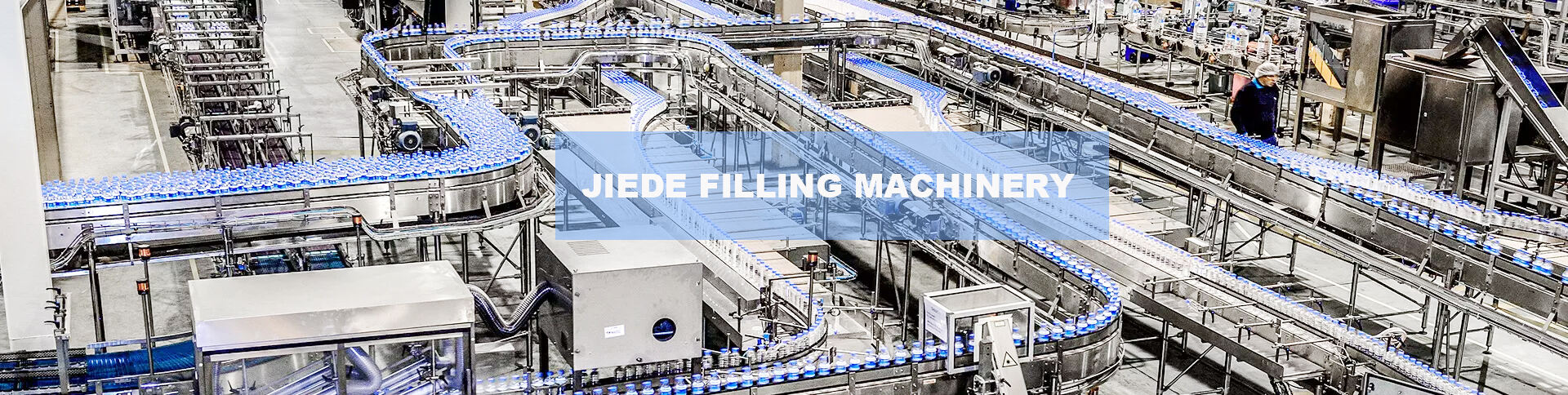

The Jiede A to Z Container Filling Equipment is the perfect remedy for any person looking to produce bottled drinking sprinkle on a large range. This innovative assembly line is designed to build the mineral water manufacturing process as efficient and structured as feasible, enabling organizations to boost their profits and increase earnings.

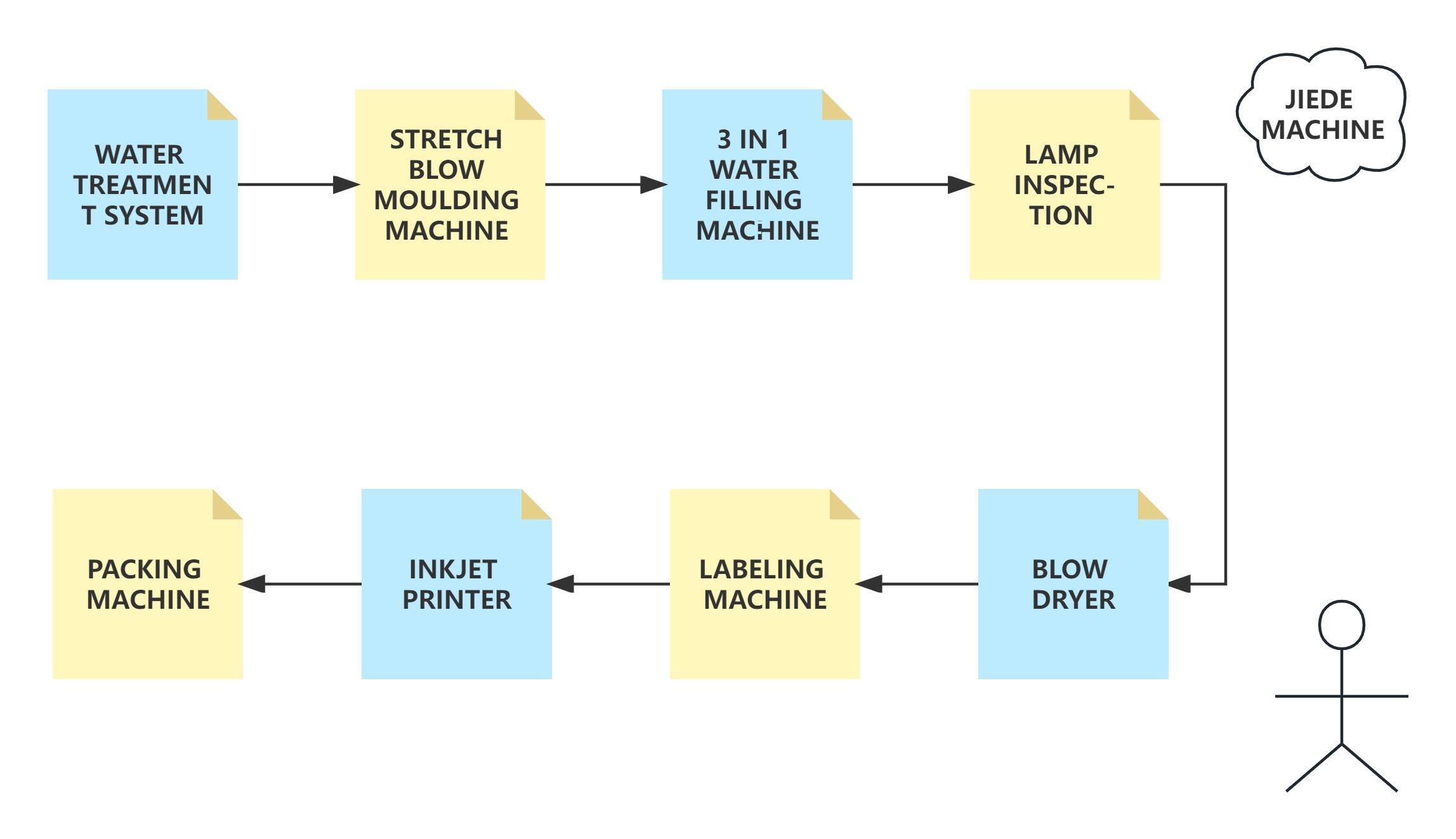

Features everything needed seriously to produce mineral water from begin to finish. This features a container blowing and machine is cleaning a sprinkle therapy system, a container filling and capping machine, and a product packaging machine that can instantly tag and shrink cover the containers.

One key feature is its high quantity of automation. The devices are designed to obtain outcomes with each other perfectly, with each element products being instantly feeding the next. What this means is that manufacturing can run 24/7 with minimal instructions, significantly lowering the need for labor and reducing manufacturing costs.

Another helpful property is its versatility. This assembly line may be used to produce a selection of bottled items, consisting of mineral sprinkle, detoxified sprinkle, and sprinkle is flavored. It may also fill containers of various dimensions, from tiny 330ml containers to big containers which can be 5-gallon.

Among one of the most considerable concerns is totally free of pollutants. Using this, you can be guaranteed that your particular sprinkle is bottled will up for a highest requirement of quality and pureness. The system uses advanced filtration technology to filter pollutants and guarantee that the sprinkle meets all quality is important.

If you are looking to take your mineral water manufacturing to the next degree, the Jiede A to Z Container Filling Equipment is an exceptional choice.

Copyright © Zhangjiagang Jiede Machinery Co., Ltd. All Rights Reserved | Blog | Privacy Policy